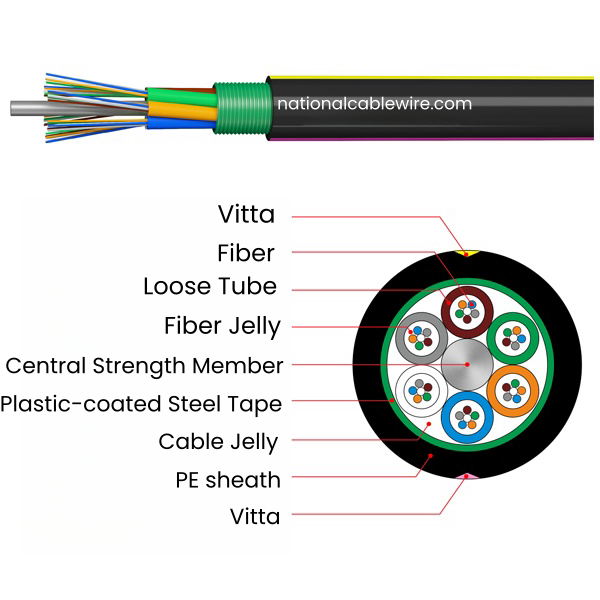

Stranded Loose Tube Steel Tape Armored Cable GYTS is a robust and highly durable fiber optic cable designed for outdoor and underground installations where enhanced protection against physical damage and moisture ingress is essential. Below is a detailed description of the cable structure, features, and applications:

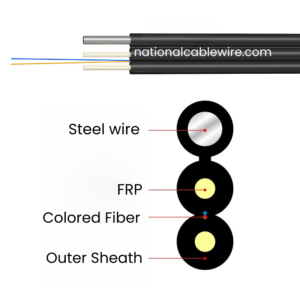

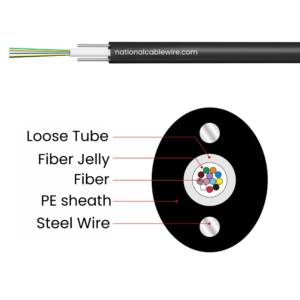

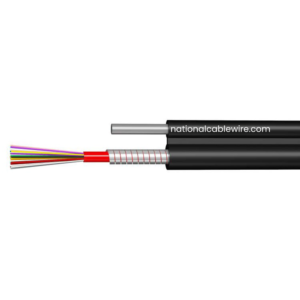

Core Structure:

- Optical Fibers: The cable typically includes 200μm or 250μm optical fibers, which can be single-mode or multimode, enabling high-speed data transmission. These fibers are housed in a loose tube made of high-modulus plastic to prevent damage from environmental and mechanical stress.

- Loose Tube: The loose tube is filled with a water-resistant filling compound to protect the fibers from moisture infiltration. This design allows the optical fibers to expand and contract with temperature fluctuations without being affected by stress or strain.

- Strength Member: At the center of the core, the cable features a non-metallic strength member, such as a Fiber Reinforced Plastic (FRP) rod, which provides tensile strength. This ensures the cable can handle external forces, such as pulling during installation, without affecting its integrity or performance.

Water Protection and Armoring:

- Stranded Tube Construction: The loose tubes and any fillers are stranded around the central strength member to form a compact, circular core. This provides a stable, durable structure that is resistant to various environmental factors.

- Steel Tape Armoring: The core is wrapped with a layer of steel tape, providing excellent mechanical protection against physical damage, rodents, and environmental hazards. The steel tape also offers a degree of grounding protection and is resistant to crushing forces, providing an additional layer of security.

- Water Protection: The cable core is filled with water-resistant gel or compound to protect the optical fibers from water ingress. This ensures the cable remains operational in wet or damp conditions, making it ideal for underground or aerial installations exposed to environmental moisture.

Outer Sheath:

- Polyethylene (PE) Sheath: The cable is completed with a durable polyethylene (PE) outer sheath. This PE sheath provides excellent resistance to UV radiation, abrasion, and chemicals, ensuring the cable performs well in harsh outdoor environments. The sheath also provides protection against physical impacts and external mechanical stress.

Key Features:

- Steel Tape Armoring: Offers superior mechanical protection against physical damage, crushing, and rodents, making the cable ideal for challenging environments.

- Water Resistance: The water-resistant filling compound and steel tape armoring provide excellent protection against moisture, ensuring the optical fibers stay dry and functional.

- Tensile Strength: The non-metallic FRP strength member ensures the cable has high tensile strength, allowing it to be used in aerial and underground installations.

- UV and Abrasion Resistance: The PE outer sheath ensures the cable is resistant to UV rays and physical wear, extending the cable’s lifespan in outdoor applications.

- Flexible and Durable Design: The stranded loose tube construction allows for flexibility during installation while maintaining long-term durability.

Applications:

- Outdoor Fiber Networks: Ideal for high-performance communication networks, including backbone and access networks.

- Underground Installations: Suitable for direct burial or installation in ducts where added protection from external damage is necessary.

- Fiber-to-the-Home (FTTH): Widely used in last-mile fiber optic applications, ensuring secure and reliable service delivery.

- Harsh Environments: Best suited for areas with high mechanical stresses, moisture, or physical hazards, such as construction sites or industrial settings.

Technical Specifications:

- Fiber Count: Typically supports 2 to 144 fibers, depending on the installation requirements.

- Cable Diameter: Varies from 9 mm to 19 mm, depending on the fiber count and construction.

- Operating Temperature: -40°C to +70°C, making it suitable for both hot and cold climates.

- Tensile Strength: High tensile strength, typically 1000 N or more, depending on fiber count and design.

- Weight: Varies from 80 to 200 kg/km, depending on the fiber count and construction.

Conclusion:

The Stranded Loose Tube Steel Tape Armored Cable GYTS is a highly protective fiber optic cable designed to withstand challenging outdoor and underground environments. With its steel tape armoring, water-resistant filling, and durable PE sheath, it ensures reliable performance even in the harshest conditions. This makes it an excellent choice for high-performance fiber optic networks that require additional mechanical protection and moisture resistance.